We provide excellent services and products

How The Glass Bottles Are Made?

Our factory is in Yuncheng County, Heze City, Shandong Province, China, we produces more than 1 million glass bottles a day. We have the most modern production factory, first-class team. Our bottles mainly include liquor bottles, beverage bottles, perfume bottles and other kinds of glass bottles. The manufacture of glass bottles includes crushing and mixing raw materials, batching, melting, forming, and annealing. The specific operation can be adjusted according to the characteristics of the glass bottle product.

Expertise cover all parts of the development cycle

-

5000+

- Inventory type -

We have a large and sufficient inventory, and if you want a bottle, our factory can fully meet your needs.

-

30000+

- Daily production volume -

The factory has four production lines that can produce simultaneously, shortening your delivery date.

-

15

- The date of delivery -

We promise to ship your order within 15 days after order placed, and provide you with an experience of receiving it quickly.

How to Make Glass Bottles Step by Step

#1 Raw materials

The raw materials used in making glass bottles are sand, soda ash, limestone and fish fillets. These materials are mixed in a certain proportion to make sodium-lime glass, however, other types of glass bottles will need to add some other materials, some need to add some dyes, compounds, some need to add heat resistant materials, pressure resistant materials, etc.

-5_0001_5bb8a19b9f3bb137a67b558408ea6f9

-5_0000_4c87724986e9216e0dc09eacb4e39d5

-5_0002_57bab5a2921663c2690c6775ba40b52

-5_0003_59a958db6bec9984c273ba87712b179

-5_0004_8905ad6eec5862a863bb76a756ef59d

-5_0005_a40417719620631dea5fb230b8dbbe5

-5_0006_b47a531234a68f176c2ea54aef55ad9

-5_0007_fc4b0b15788d5ae0a3931eb6c651cc4

#2 Ingredients for making glass bottles

The raw materials are collected and prepared and put into the hopper machine for mixing. The appropriate amount of the mixture is then placed in the batching chamber and fed into the melting furnace on a conveyor belt. The ingredient mixing part must be accurate to ensure that all bottles are of the same quality. Their size depends on the shape, weight and quantity of the bottle.

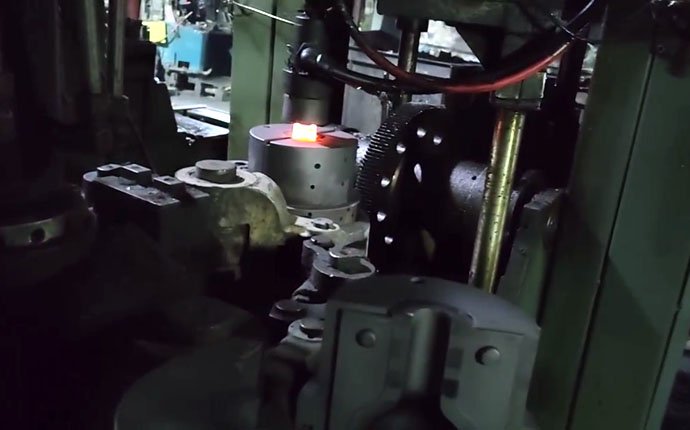

#3 Glass melts during the production of glass bottles

The melting stage is carried out in a heating furnace at a high temperature of about 1600°C. Water evaporates, organic matter burns, and the rest melts to form molten glass. Finally, the molten glass is cooled to achieve viscosity in preparation for molding. All our stoves are fully mechanized. Temperature Settings are controlled by our engineers in the integrated control room.

#4 Blow glass molding

First, cut the mixture into equal-sized shapes with a timed blade. The gob falls into different slots in a separate slicer. Each slot contains a molding die. The final shape is achieved by blow and blow or press and blow.

#5 Annealing and Conditioning Processes in Glass Bottle Manufacturing

After glass production, a strict temperature control process is required, which involves slowly heating the glass and gradually cooling it to a temperature below the strain point of the glass.

Annealing can effectively reduce the damage rate of glass, weaken internal and external pressure, and also achieve good settlement.

#6. Surface Treatment

After the completion of glass bottle production, surface treatment can be carried out, which not only serves a decorative purpose but also prevents wear and tear.Common surface treatment methods include Engraving、Screen Printing、Spray Painting、Crackling、Electroplating、Baking、Frosting、Matting.